First, we receive a shipment of 100% Kona Cotton from Robert Kaufman. We primarily print on white and natural colored fabric.

Not very interesting yet, I know. But this is the foundation for our original hand-printed panels.

Before they are printed, they are cut to size. We print our panels on fat quarter size (18" x 22") pieces of fabric.

| |

| The lovely Maddie is hand cutting each panel one-by-one on a long table. |

| ||

|

|

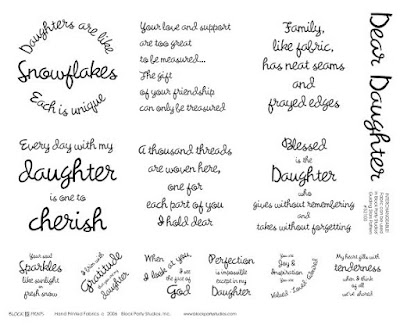

| Our Dear Daughter panel design. |

After the ink is applied by silk screening and has gone through a dryer, the fabric is ready to be folded and packaged.

|

| Maddie folding fabric panels one-by-one |

And now they're ready for you to use!

Thanks for sharing. Very interesting.

ReplyDeleteIts a terrific enjoyment studying your submit. Its packed with info I'm seeking in addition to I enjoy submit a comment which "The content material of one's submit is usually awesome" Wonderful function.

ReplyDeleteRegards: chiffon